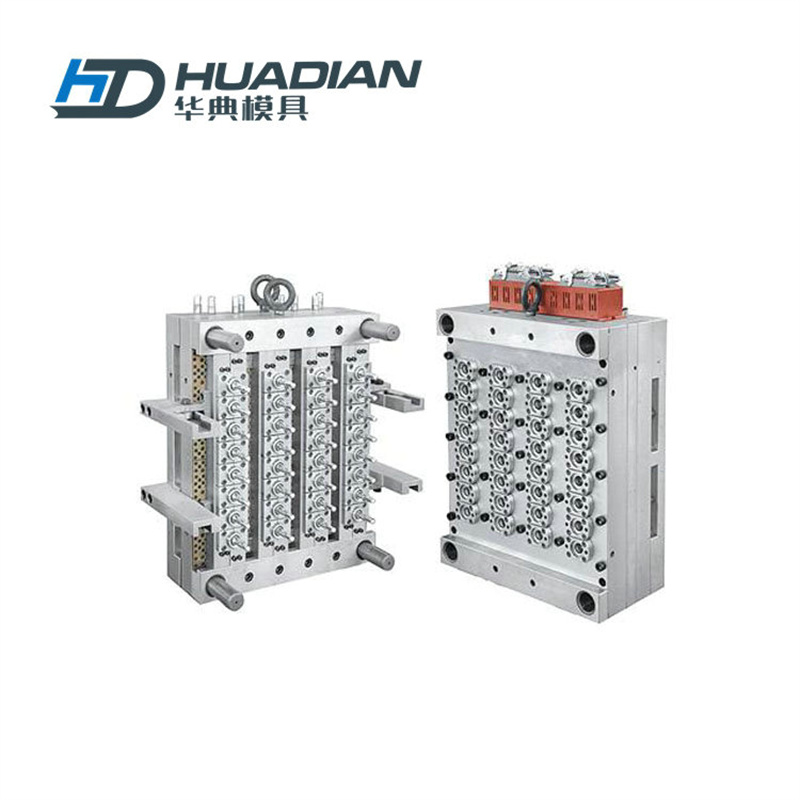

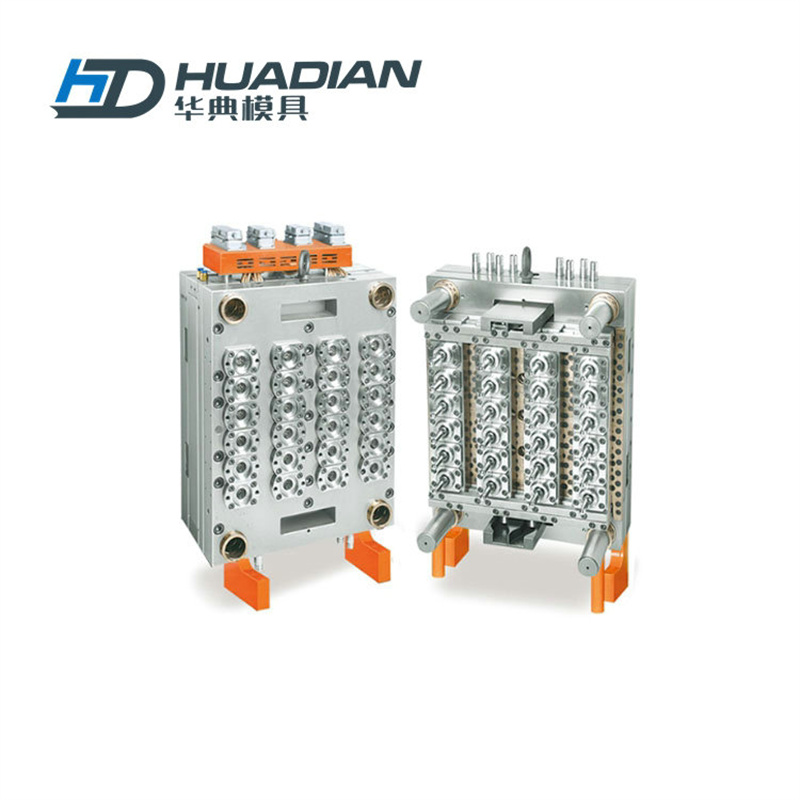

Multi Cavities Cosmetic Customized Perform Mold

Specifications

| Cavity | Perform | Mold Size | Mold Weight | Cycle Time | |||

| Weight(g) | Neck(mm) | Height(mm) | Width(mm)) | Thickness(mm) | (kg) | (sec) | |

| 2(1*2) | 720 | 55 | 470 | 300 | 608 | 330 | 125 |

| 4(2*2) | 720 | 55 | 490 | 480 | 730 | 440 | 130 |

| 8(2*4) | 16 | 28 | 450 | 350 | 410 | 475 | 18 |

| 12(2*6) | 16 | 28 | 600 | 350 | 415 | 625 | 18 |

| 16(2*8) | 21 | 28 | 730 | 380 | 445 | 690 | 22 |

| 24(3*8) | 28 | 28 | 770 | 460 | 457 | 1070 | 28 |

| 32(4*8) | 36 | 28 | 810 | 590 | 515 | 1590 | 28 |

| 48(4*12) | 36 | 28 | 1070 | 590 | 535 | 2286 | 30 |

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

HuaDian Mold - mold data

| NO. | Name | Desciption | Hardness | |

| 1 | Mold base material | P20 | 28-32 | |

| 2 | Core,cavity | S136 | 48-52 | |

| 3 | Screw neck | S136 | 48-52 | |

| 4 | Cooling mode | Mold core, neck cooling | ||

| 5 | Cooling mode for core plate and cavity plate | 1 in, 1 out | ||

| 6 | Out of center(MM) | "+/-0.08MM | ||

| 7 | Cycle injection time | 8-23 Seconds | ||

| 8 | Delivery time | 55 Days after desgins confirmed | ||

HUADIAN's Multi Cavities Cosmetic Customized Perform Mold is a high-quality product made of P20 mold with S136 core, cavity, and screw opening, ensuring superior precision and durability during PET bottle production. With the help of CAD and PRO-E design software, customers can personalize their molds according to their unique requirements, ensuring optimal performance and providing a hassle-free installation. This product is designed with a hot runner system that reduces waste and improves production efficiency, making it ideal for manufacturers requiring high-volume production.

HUADIAN's Multi Cavities Cosmetic Customized Perform Mold is an innovative product designed to produce high-quality PET bottles. Made of P20 mold with S136 core, cavity, and screw opening, and a hot runner system, this mold enables manufacturers to boost efficiency while minimizing waste during production. Additionally, it is customizable, ensuring personalized performance for individual needs.

HUADIAN's Multi Cavities Cosmetic Customized Perform Mold is a high-quality product intended to deliver superior precision and durability during PET bottle production. The mold material is made of P20, which ensures a superior mold performance and productive life span. Additionally, S136 core, cavity, and screw opening guarantee that production is stable, efficient with optimum precision during PET bottle production.

This product also promotes high production efficiency and minimal waste with the inclusion of a hot runner system. The waste reduction is attributed to the hot runner system approach where the plastic is partially melted via high-pressure hot runners to form the required shape, hence by reducing excess plastic in the process hence catering for cost reduction.

The Multi Cavities Cosmetic Customized Perform Mold is designed to enable effortless customization, making it an excellent option for personalized production needs. Customers can use CAD and PRO-E design software, and demonstrate the desired product characteristics, which the team from HUADIAN can implement in the mold design to meet their needs, preferences, and specifications.

One of the most significant advantages of the Multi Cavities Cosmetic Customized Perform Mold is the ease of installation. The installation manual is user-friendly and follows a simple approach to installing this amazing product. This feature, therefore, makes it easy for operators to handle the product, which may result in higher production outputs.

Conclusion:

HUADIAN's Multi Cavities Cosmetic Customized Perform Mold is an innovative P20 molded product suitable for the production of quality PET bottles. The inclusion of a hot runner system ensures the minimum use of plastics, minimal waste, improved accuracy, and increased production efficiency in large scale productions. Additionally, CAD and PRO-E design software guarantee optimal customization for customers. Finally, the product's ease of installation and user-friendly manual make this mold a viable option for personalized production needs.