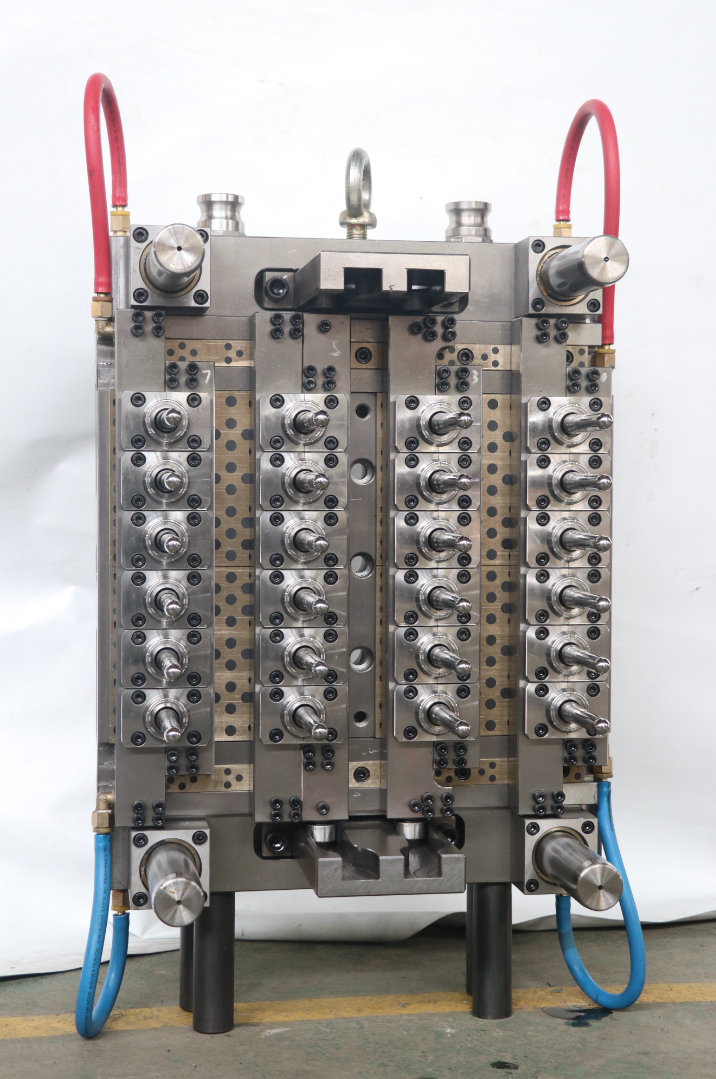

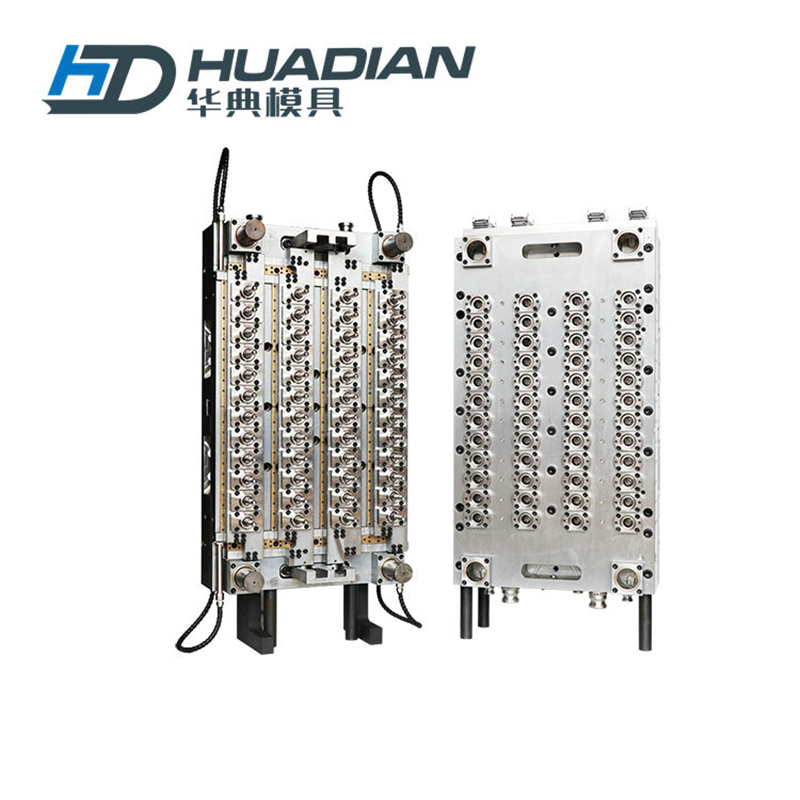

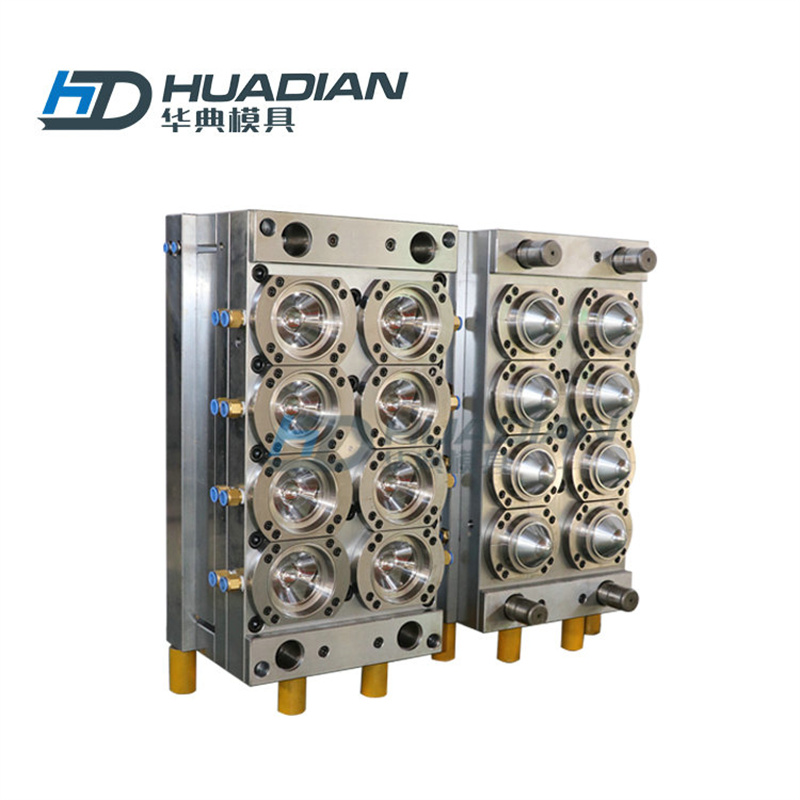

Launched 24-cavity self-locking common bottle preform mold

Specifications

| Cavity | Perform | Mold Size | Mold Weight | Cycle Time | |||

| Weight(g) | Neck(mm) | Height(mm) | Width(mm)) | Thickness(mm) | (kg) | (sec) | |

| 2(1*2) | 720 | 55 | 470 | 300 | 608 | 330 | 125 |

| 4(2*2) | 720 | 55 | 490 | 480 | 730 | 440 | 130 |

| 8(2*4) | 16 | 28 | 450 | 350 | 410 | 475 | 18 |

| 12(2*6) | 16 | 28 | 600 | 350 | 415 | 625 | 18 |

| 16(2*8) | 21 | 28 | 730 | 380 | 445 | 690 | 22 |

| 24(3*8) | 28 | 28 | 770 | 460 | 457 | 1070 | 28 |

| 32(4*8) | 36 | 28 | 810 | 590 | 515 | 1590 | 28 |

| 48(4*12) | 36 | 28 | 1070 | 590 | 535 | 2286 | 30 |

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

HuaDian Mold - mold data

| NO. | Name | Desciption | Hardness |

| 1 | Mold base material | P20 | 28-32 |

| 2 | Core,cavity | S136 | 48-52 |

| 3 | Screw neck | S136 | 48-52 |

| 4 | Cooling mode | Mold core, neck cooling | |

| 5 | Cooling mode for core plate and cavity plate | 1 in, 1 out | |

| 6 | Out of center(MM) | "+/-0.08MM | |

| 7 | Cycle injection time | 8-23 Seconds | |

| 8 | Delivery time | 45 Days after desgins confirmed | |

With years of production experience and a commitment to operating with integrity and quality first, we are pleased to present to you our latest innovation in the field of PET preform molds - 24-cavity self-locking universal preform mold. The mold's combination of thermal stability, durability and user-friendly design will revolutionize the preform production process.

Our 24-cavity self-locking ordinary bottle preform mold has reasonable design and structure to ensure easy operation for customers. With its high production time and efficiency, it maximizes output while minimizing waste. The inclusion of a hot runner system significantly reduces material waste, making it an environmentally friendly choice for your manufacturing needs.

We understand the importance of delivering products that are built to last, and our 24-cavity self-locking universal preform mold is no exception. Its excellent thermal stability guarantees consistent and high-quality preform production, ensuring your final product meets the highest standards. This mold is durable and can withstand the most demanding manufacturing environments, giving you a long-lasting solution.

In today's fast-paced industry, time is of the essence. That's why our 24-cavity self-locking universal preform mold is designed to optimize production time, allowing you to meet tight deadlines and increase productivity. The easy-to-use features of our molds further increase efficiency, allowing your operators to focus on other critical tasks, ultimately saving you time and money.

We are confident in the superiority and reliability of our products and believe that the 24-cavity self-locking universal preform mold is an important asset for any company involved in preform production. Our commitment to quality extends beyond the mold itself, as we also prioritize customer support and satisfaction. Our team of experts is ready to help you every step of the way, answering any questions or addressing any concerns you may have.

At [Company Name], our goal is to provide our customers with innovative solutions for their manufacturing needs. Our 24-cavity self-locking universal preform mold demonstrates this commitment. This mold combines cutting-edge technology, durability and user-friendly design to take your preform production to new heights.

Don't miss the opportunity to take your production process to the next level. Contact us today and let us show you how our 24-cavity self-locking universal preform mold can revolutionize your business. When we work together, we can achieve great things and pave the way for a more efficient and sustainable future.