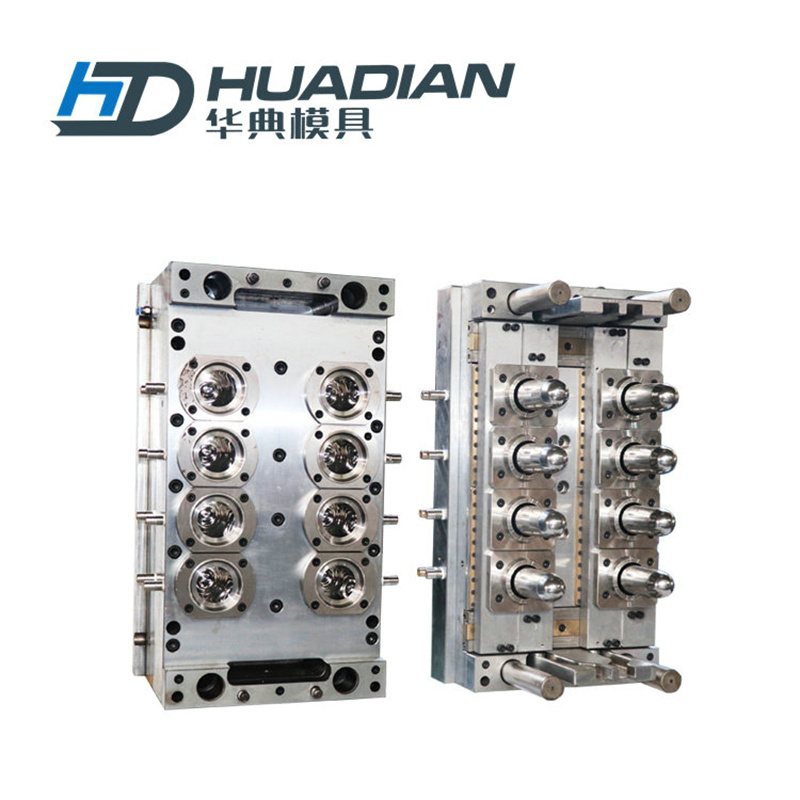

Big Oil bottle Perform Mold

Specifications

| 0il Bottle Size | 1L-2.5L | ||||||

| 1.8L- 2.5L | |||||||

| 10L | |||||||

| 20L | |||||||

| Neck | 32MM, 37MM, 46M, 46MM | ||||||

| 62MM, 72MK | |||||||

| 0il Bottle Eight | 20G, 25G, 28G, 30G, 35G, 40G, 40G, 43G | ||||||

| 50G, 55C, 600, 63G, 65C. 680, 700, 756, 77G, 82G | |||||||

| 85G, 90G, 93G, 95G, 100G, 120G, 140G, 145G, 150G | |||||||

| 175C, 230C, 245G, 250G | |||||||

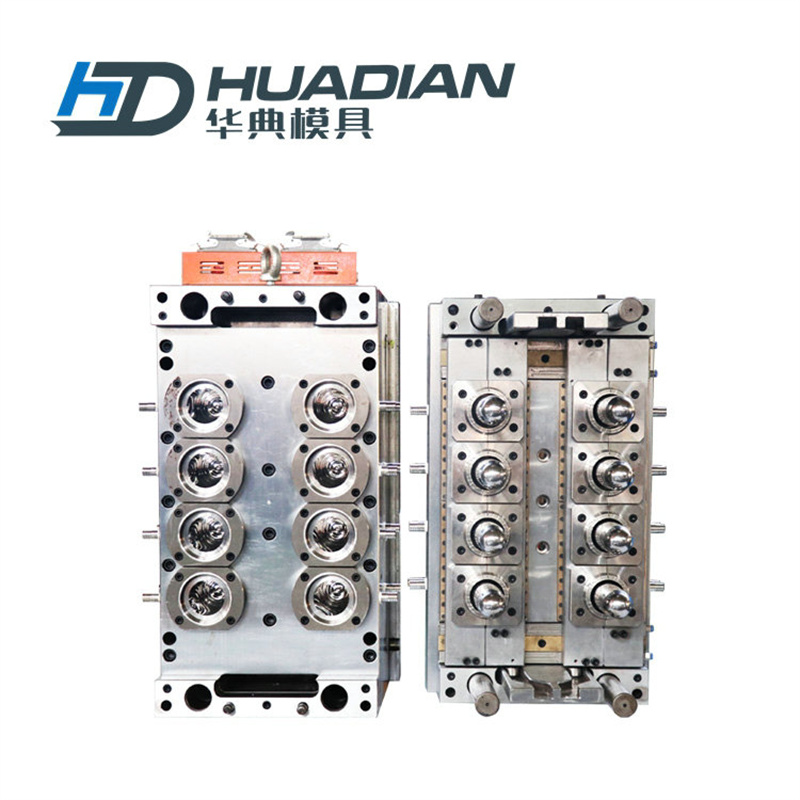

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

mold data

| Name | Pet Oil Bottl Perform Mold |

| Cavity And Core | S136(8, 12, 24, 48, 96HRC) |

| Mold Shelf | P20 |

| Cavity Qty | As Customi Zed |

| product Standard | Lkm, Dme, Hasco |

| Rotary Wheel Type | Hot Board |

| Cycle Time | Short |

| Software | UG, PROE, CAD |

| Perform Material | Pet |

| Perform SiZe | As Customi Zed |

| Working Life | 3-4Million |

| Delivery Time | 45-50DaysAYS |

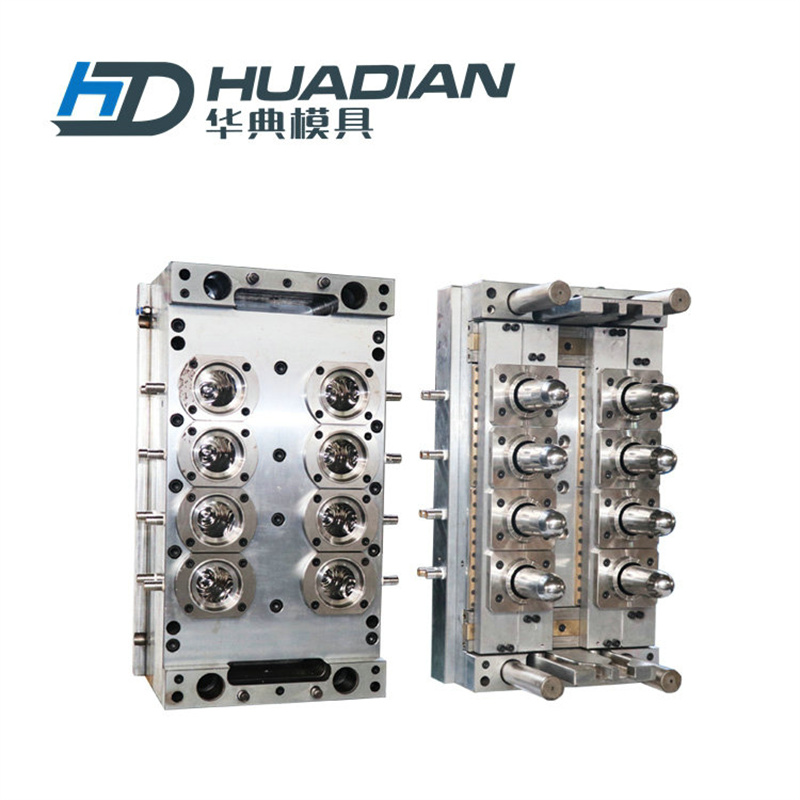

This mold is suitable for production capacity of 1L to 5L of various shapes of oil bottles. With a 16-chamber design, it is capable of producing multiple products at once, greatly improving production efficiency and maximizing profit for manufacturers.

Big Oil Bottle Perform Mold also has the following characteristics:

- High quality materials and design make the surface of the product flat and smooth

- Easy to install and remove without additional tools

- Minimize product costs and improve users' profits

- Can be customized and adapted to various injection molding machines according to customer needs

In addition, each mold after full testing and trial production, can produce accurate and high quality products, so as to meet the different needs of users. Big Oil Bottle Perform Mold also provides technical support and mold debugging support to create the best production benefits for users and ensure a perfect injection molding process.