8 Cavities Oil bottle PET Perform Mold

Specifications

| 0il Bottle Size | 1L-2.5L | ||||||

| 1.8L- 2.5L | |||||||

| 10L | |||||||

| 20L | |||||||

| Neck | 32MM, 37MM, 46M, 46MM | ||||||

| 62MM, 72MK | |||||||

| 0il Bottle Eight | 20G, 25G, 28G, 30G, 35G, 40G, 40G, 43G | ||||||

| 50G, 55C, 600, 63G, 65C. 680, 700, 756, 77G, 82G | |||||||

| 85G, 90G, 93G, 95G, 100G, 120G, 140G, 145G, 150G | |||||||

| 175C, 230C, 245G, 250G | |||||||

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

mold data

| Name | Pet Oil Bottl Perform Mold |

| Cavity And Core | S136(8, 12, 24, 48, 96HRC) |

| Mold Shelf | P20 |

| Cavity Qty | As Customi Zed |

| product Standard | Lkm, Dme, Hasco |

| Rotary Wheel Type | Hot Board |

| Cycle Time | Short |

| Software | UG, PROE, CAD |

| Perform Material | Pet |

| Perform SiZe | As Customi Zed |

| Working Life | 3-4Million |

| Delivery Time | 45-50DaysAYS |

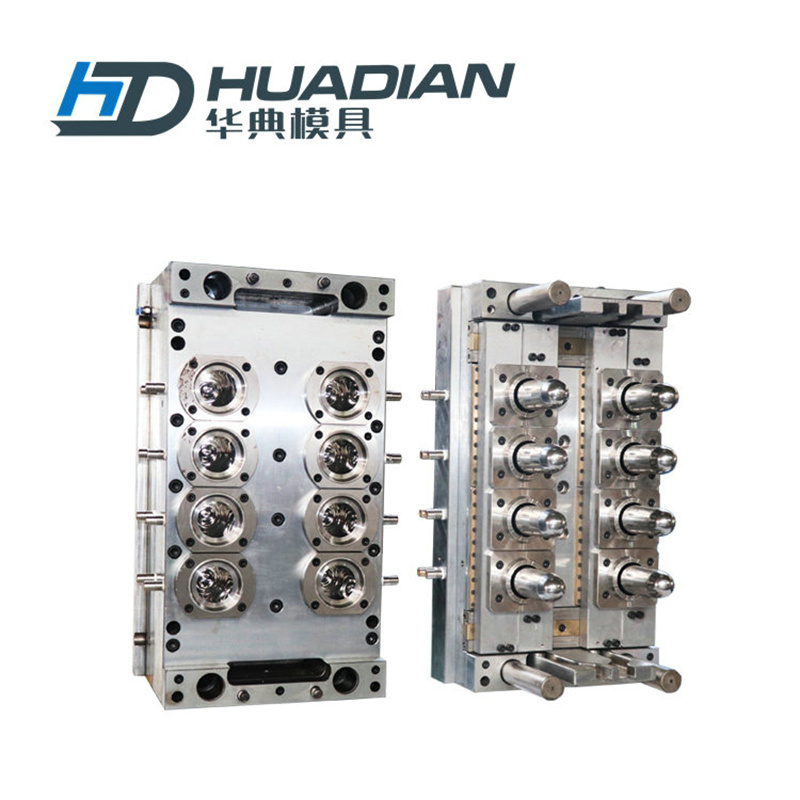

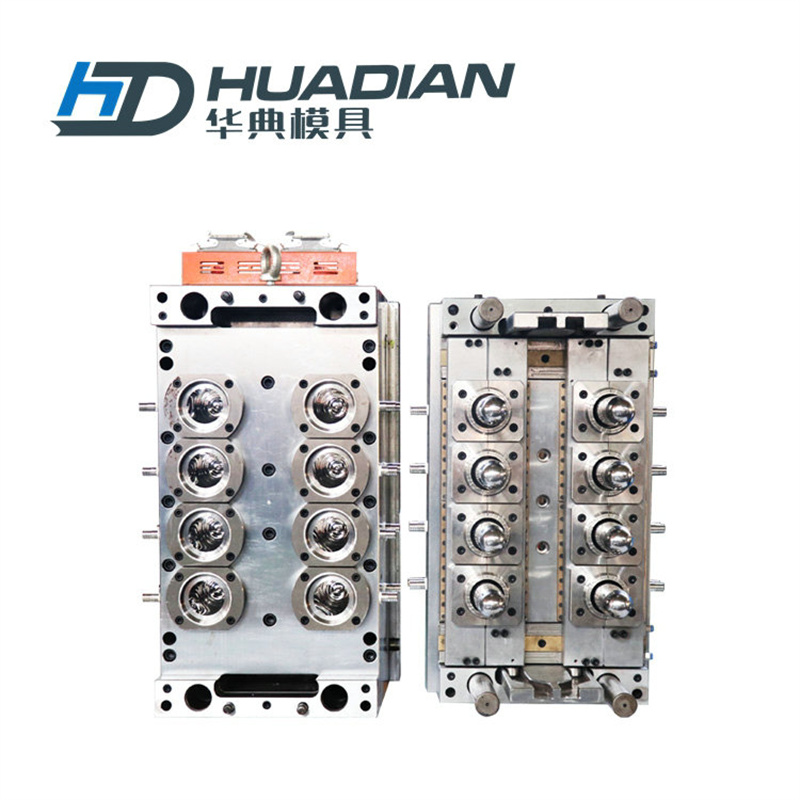

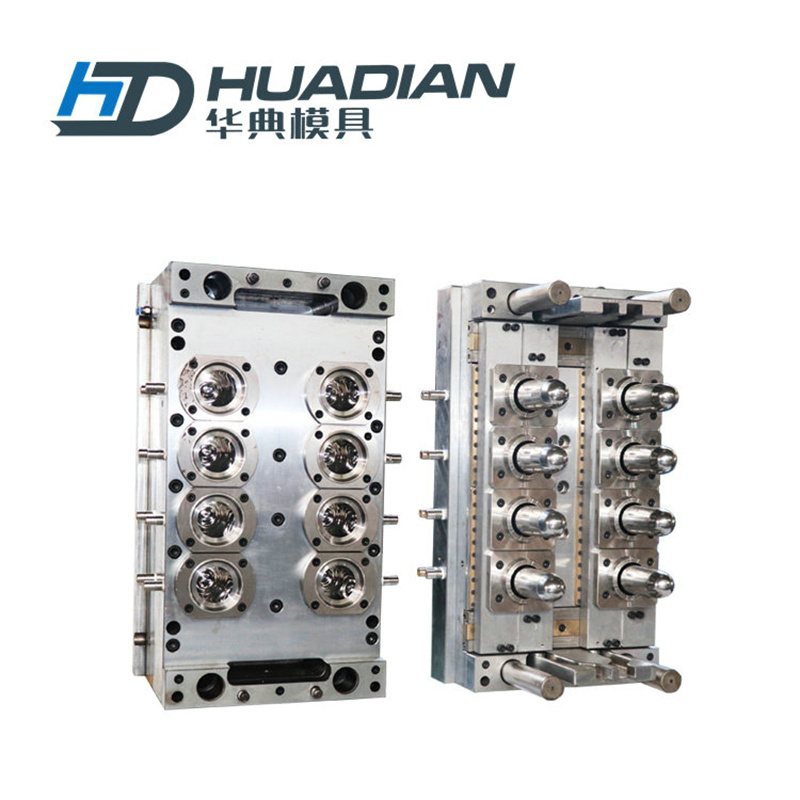

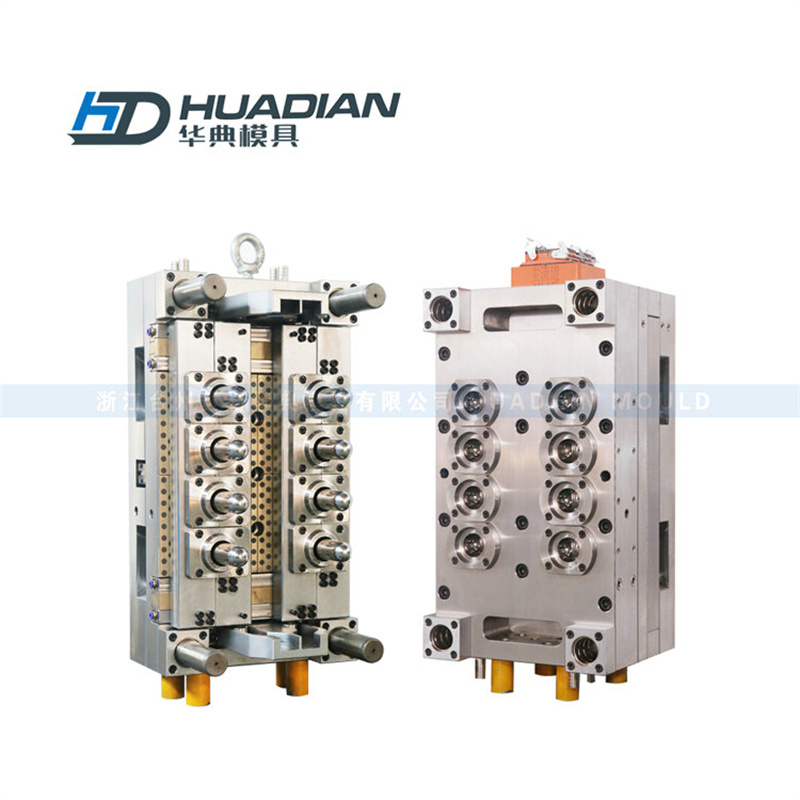

HUADIAN's 8 Cavities Oil Bottle PET Perform Mold is a high-quality product made of PET material with P20 mold, S136 core, cavity, and screw opening, providing superior precision and stability during PET bottle production. This product has eight cavities arranged in a 4x2 matrix layout, which makes it an ideal option for large-scale production. Moreover, HUADIAN uses CAD, PRO-E, and UG design software to support personalized customization according to the customer's requirements, ensuring optimal performance and installation.

HUADIAN's 8 Cavities Oil Bottle PET Perform Mold is a high-quality product made of PET material with a hot runner system, P20 mold and S136 core, cavity, and screw opening, ensuring superior precision and durability while producing PET bottles. With eight cavities available in a 4x2 matrix layout, it is ideal for mass production, making it an excellent option for manufacturers requiring high-volume production. HUADIAN's CAD, PRO-E, and UG design software provide personalized customization, optimizing the mold's performance and installation.

HUADIAN's 8 Cavities Oil Bottle PET Perform Mold is a reliable and efficient product that offers superior precision and stability during the PET bottle production process. The mold is made of high-quality PET material that serves as a foundation for producing high-quality PET bottles. The hot runner system design reduces wastage and improves production efficiency, ensuring that raw materials are used efficiently.

P20 mold and S136 core, cavity, and screw opening guarantee superior precision and stability when producing PET bottles. The eight cavities, arranged in a 4x2 matrix, make it an optimal option for large-scale production. HUADIAN's CAD, PRO-E, and UG design software enable personalized customization, ensuring optimal performance and installation.

One key advantage of the 8 Cavities Oil Bottle PET Perform Mold is that it is highly reliable and low-maintenance, making it an ideal choice for high-volume production. The mold is designed with durability in mind, ensuring that it withstands consistent production environments with minimal maintenance requirements. This makes it cost-effective in the long run, making it an ideal option for businesses seeking to remain competitive in the market.

In addition to being reliable and low-maintenance, the mold is easy to use and operate. The installation and operation manual is clear and concise, providing a simple approach to installation and offering helpful tips along the way. Operators can monitor the parameters that fall within pre-defined ranges, ensuring consistent PET bottle production.

Conclusion:

HUADIAN's 8 Cavities Oil Bottle PET Perform Mold is a reliable and efficient product that provides superior precision and stability during the PET bottle production process. With a hot runner system design that reduces raw material wastage and P20 mold and S136 core, cavity, and screw opening that guarantee superior precision, this product is ideal for high-volume production. Personalized customization is available through the use of CAD, PRO-E, and UG design software, ensuring optimal performance and installation. Moreover, the low-maintenance requirements, ease of operation, and a comprehensive installation and operation manual make the 8 Cavities Oil Bottle PET Perform Mold an excellent investment for businesses seeking long-term, reliable PET bottle production.