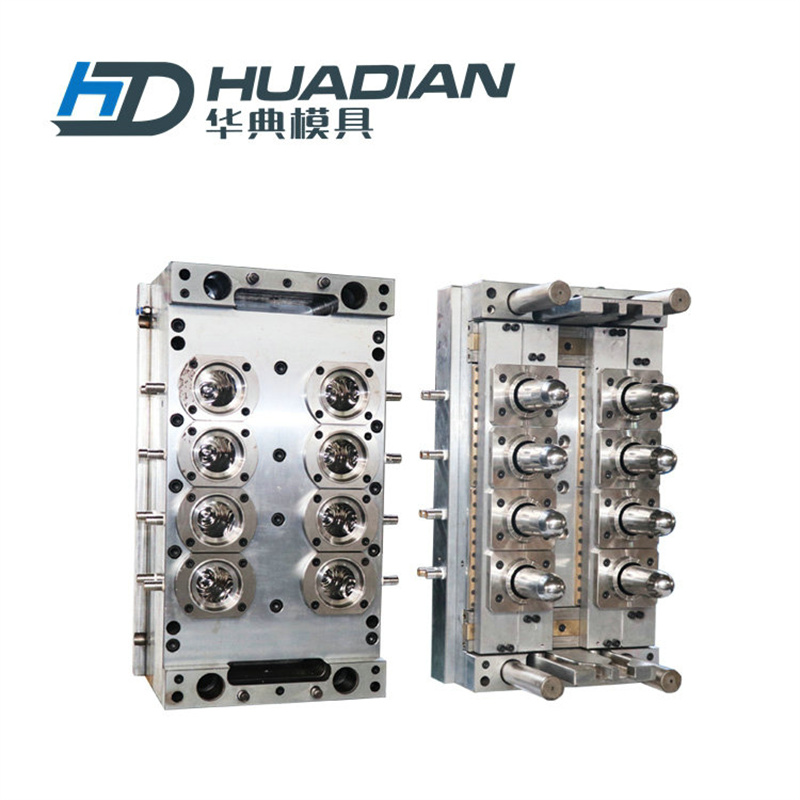

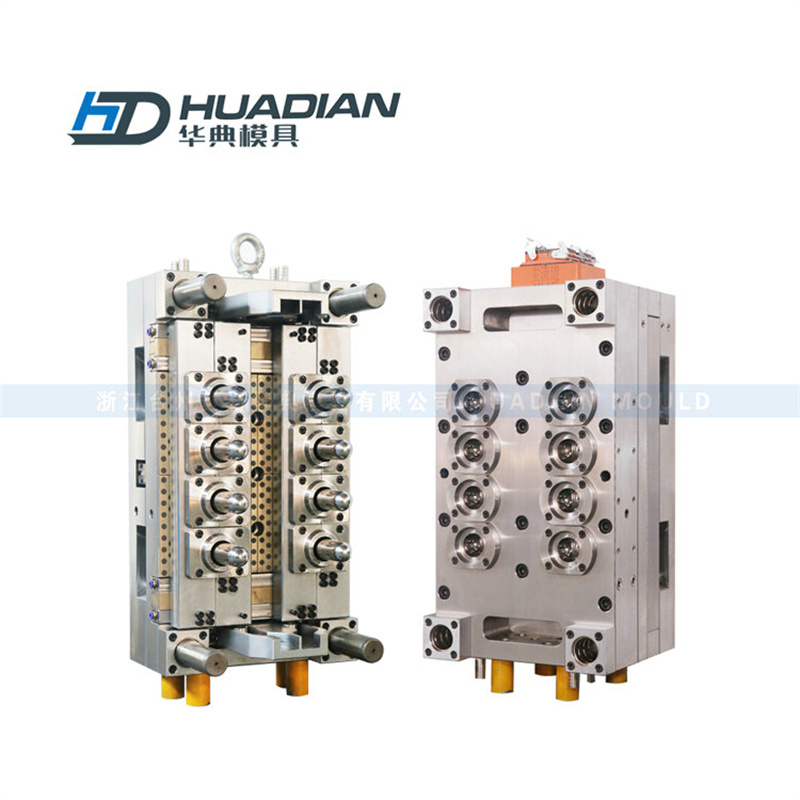

8 Cavities Oil bottle Perform Mold

Specifications

| 0il Bottle Size | 1L-2.5L | ||||||

| 1.8L- 2.5L | |||||||

| 10L | |||||||

| 20L | |||||||

| Neck | 32MM, 37MM, 46M, 46MM | ||||||

| 62MM, 72MK | |||||||

| 0il Bottle Eight | 20G, 25G, 28G, 30G, 35G, 40G, 40G, 43G | ||||||

| 50G, 55C, 600, 63G, 65C. 680, 700, 756, 77G, 82G | |||||||

| 85G, 90G, 93G, 95G, 100G, 120G, 140G, 145G, 150G | |||||||

| 175C, 230C, 245G, 250G | |||||||

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

mold data

| Name | Pet Oil Bottl Perform Mold |

| Cavity And Core | S136(8, 12, 24, 48, 96HRC) |

| Mold Shelf | P20 |

| Cavity Qty | As Customi Zed |

| product Standard | Lkm, Dme, Hasco |

| Rotary Wheel Type | Hot Board |

| Cycle Time | Short |

| Software | UG, PROE, CAD |

| Perform Material | Pet |

| Perform SiZe | As Customi Zed |

| Working Life | 3-4Million |

| Delivery Time | 45-50DaysAYS |

One of the most common plastic products in the world today is oil bottles. In order to produce high quality Oil bottle, increase production efficiency and production cost, 8 Cavities Oil bottle Perform Mold came into being.

Product details:

The mold is made of high quality steel, especially the surface of the steel has been treated to give it better hardness and corrosion resistance. In addition, the design of each part of the mold is carefully calculated to ensure that the size, shape and quality of the oil bottle are best guaranteed.

Product features:

As an efficient, flexible, economical and practical mold, its characteristics are as follows:

1. It can provide high output, producing 8 oil bottles at a time;

2. Mold design is suitable for all types of oil bottles;

3. Capable of producing high quality oil bottles without any damage to their characteristics;

4. Long life and durability;

5. Mold design and structure are easy to use and maintain.

Product advantages:

The 8-cavity oil bottle molding mold has the following four advantages:

1. High production efficiency: 8 oil bottles can be produced, which can complete more production tasks in the same time and reduce production costs.

2. Provide better product quality: The mold design ensures the size and shape of the oil bottle, so that it cannot deviate from its own quality standards, so as to produce high quality products.

3. Better environmental protection: The mold uses high-quality materials to reduce the waste of energy and raw materials in the oil bottle forming process.

4. Economical and practical: Compared with a single mold, the production of 8 oil bottles at a time can greatly reduce the cost and time.

Product application:

8 cavity oil bottle molding mold can be widely used in various types and specifications of oil bottle production process, such as: acrylic, PET, PE, PC and other oil bottle production. No matter what type of oil bottle you are producing, this mold can help you increase production efficiency, ensure high quality products, reduce costs, and provide better environmental performance.

Product installation:

The 8-cavity oil bottle molding mold is very simple to install, just according to the instructions in the steps, follow the instructions. To ensure correct installation, you can also ask engineers to help you install and perform necessary tests and adjustments.

In short, the 8 cavity oil bottle molding mold is a very practical equipment, can provide substantial help for the oil bottle manufacturers. If you are looking for a solution to improve production efficiency, reduce costs and guarantee product quality, then this mold will be a good choice.