8 Cavities Jar Air Sealed Perform Mold

Jar Size

- NECK: 60.5mm 70mm 70mm 86mm 86mm 110mm 70mm 86mm 63mm 120mm 97mm 86mm 120mm 120mm 120mm 122mm 120mm 148mm 62mm 71.5mm 71.5mm 71.5mm 71.5mm

- Weight: 30g 35g 43g 43g 52g 52g 53g 65g 65g 85g 88g 90g 95g 100g 120g 160g 170g 193g 150g 175g 250g 270g 290g

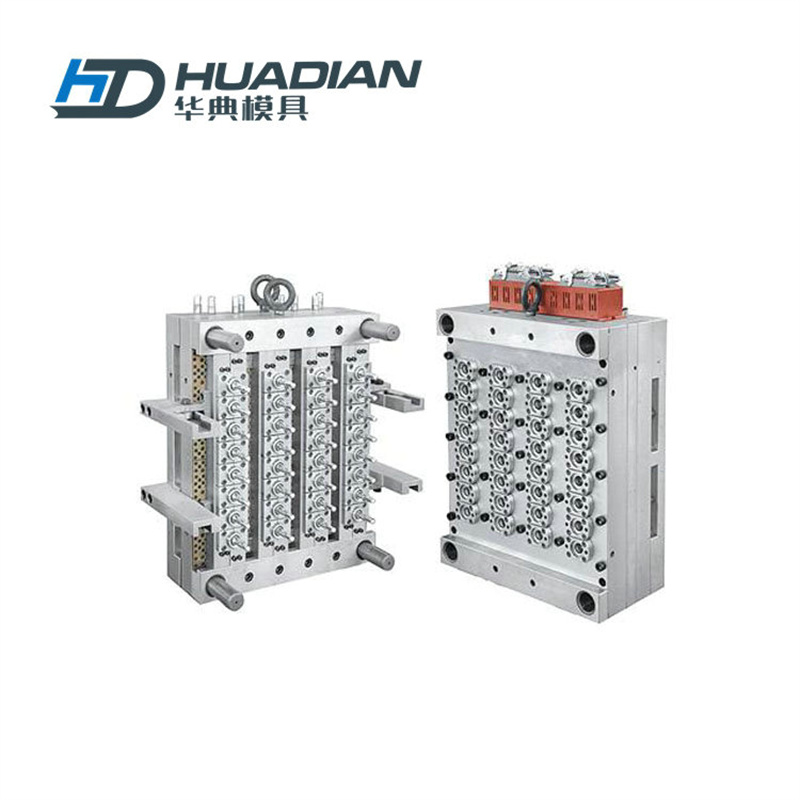

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

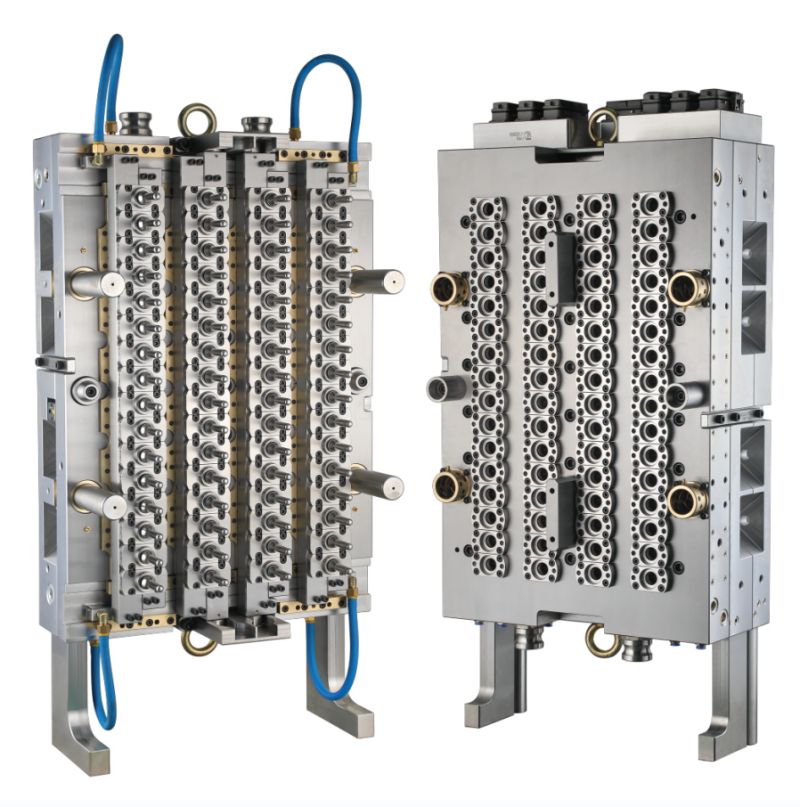

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

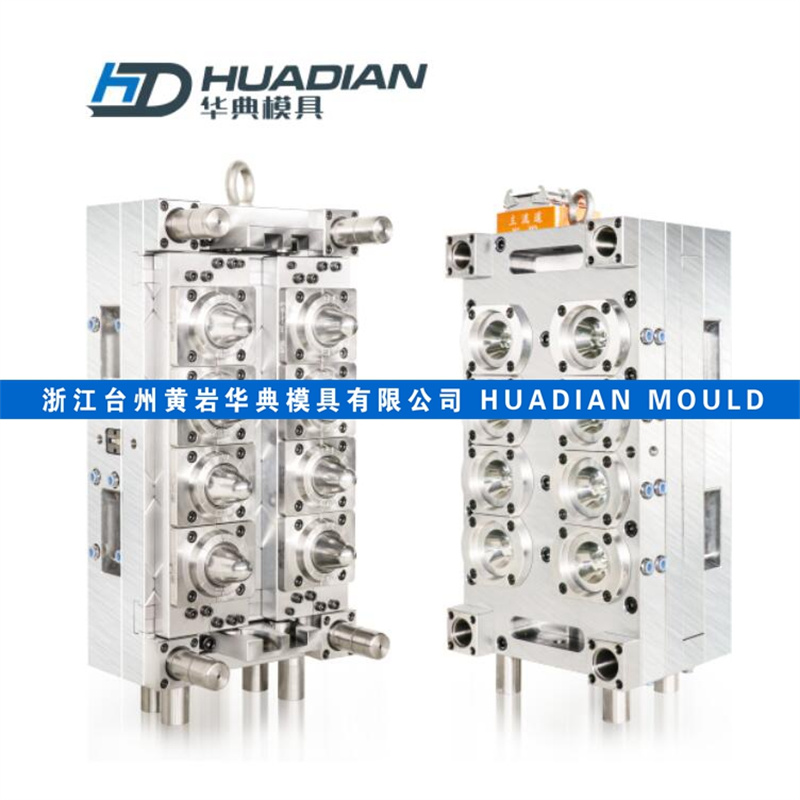

The8 Cavities Jar Air Sealed Perform Mold produced by HUADIAN is a high-quality product made of PET material with P20 mold and S136 core, cavity, and screw opening, providing first-class precision and stability for high-quality PET jar production. The mold has 8 cavities with a 4x2 matrix layout, which is ideal for large-scale production. HUADIAN uses professional CAD, PRO-E, and UG design software to support personalized customization design that is easy to install and operate.

HUADIAN's 8 Cavities Jar Air Sealed Perform Mold is made of high-quality PET material and has a hot runner design that significantly reduces material waste and increases production efficiency. With P20 mold and S136-made core, cavity, and screw opening, the produce has a high level of quality assurance for PET jar production. Besides, the 8-cavity design with a 4x2 matrix layout is perfect for large-scale production, where HUADIAN’s professional design software enables easy customization without any compromise on precision and stability.

The 8 Cavities Jar Air Sealed Perform Mold produced by HUADIAN is a high-quality PET material product with a hot runner system design, which reduces material waste and improves production efficiency. The hot runner design enables even and stable heating for better material flow, eliminating cold runners, sprues, or gates, ultimately leading to smoother production and better product quality.

The use of P20 molds and S136-made core, cavity, and screw opening offers top-of-the-line first-class precision and stability for high-quality PET jar production. The mold's eight cavities with 4x2 matrix layout offers enough capacity to satisfy large-scale production requirements, depending on the specific needs of each customer. Additionally, CAD, PRO-E, and UG design software are used by HUADIAN to optimize the design of the mold based on the customer's specific requirements.

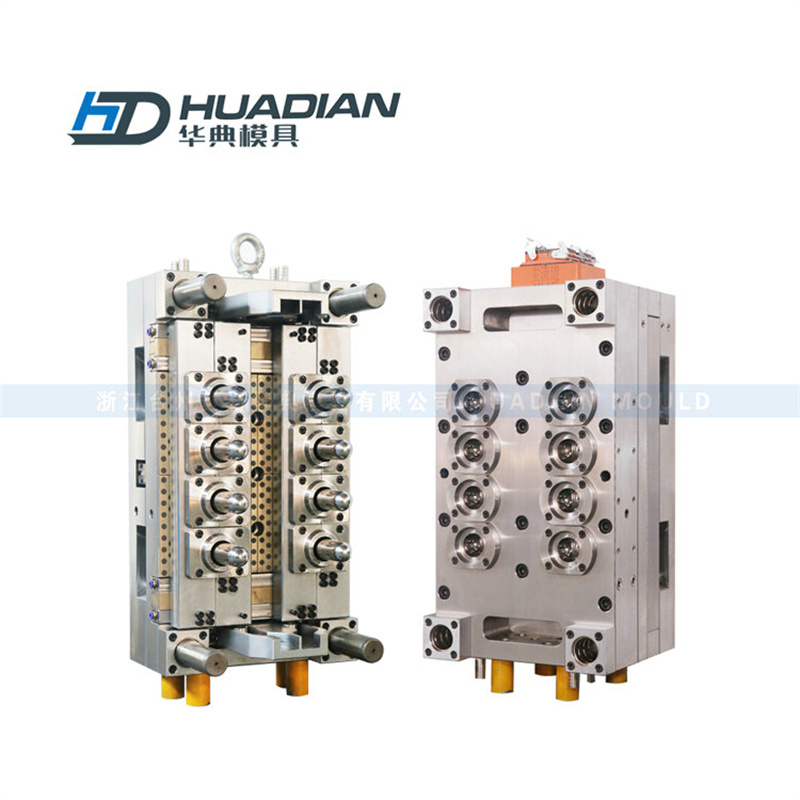

Another advantage of HUADIAN's 8 Cavities Jar Air Sealed Perform Mold is that installation and operation are easy for even inexperienced operators. The installation and operating manual of the mold is comprehensive, covering every step clearly with a straightforward approach. By only monitoring parameters that fall within the pre-defined range, ensuring production quality and stability over a long-term period.

Conclusion:

The 8 Cavities Jar Air Sealed Perform Mold produced by HUADIAN is a high-quality and easy-to-operate product. The mold, made of PET material and designed with a hot runner system, provides a better consumption of raw materials, reduces material waste, and increases production efficiency. The P20 molds and S136-made core, cavity, and screw opening enable first-class precision and stability for the production of high-quality PET jars. The 8-cavity design with a 4x2 matrix layout offers ample capacity for large-scale production while providing the customer with the freedom to customize the design. HUADIAN has a high reputation in the production of PET jars, with professional technology expertise, modern production equipment, and advanced manufacturing experience, providing high-quality, high-precision, and stable PET jars.