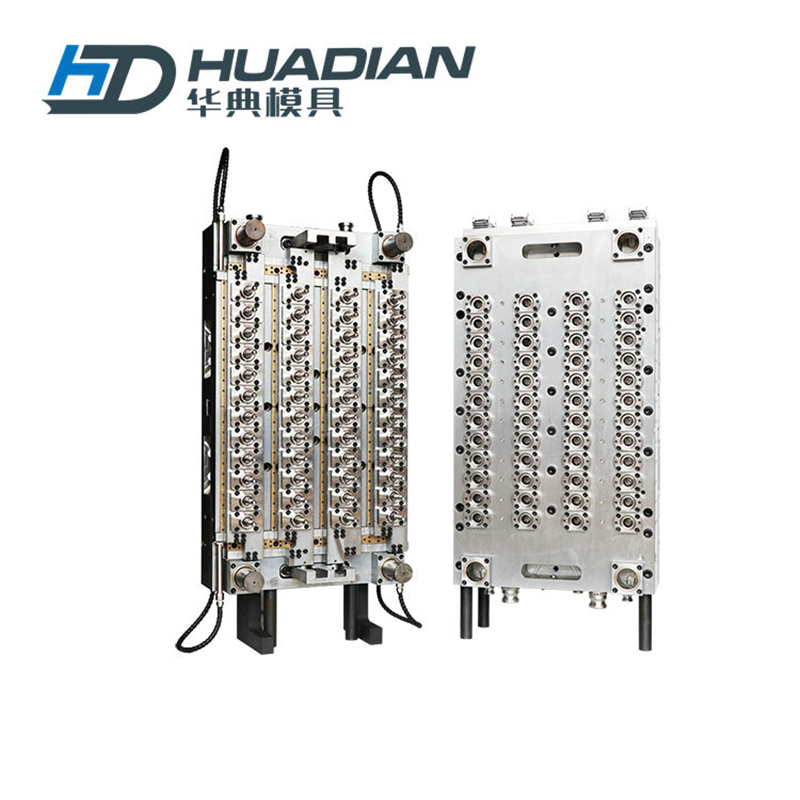

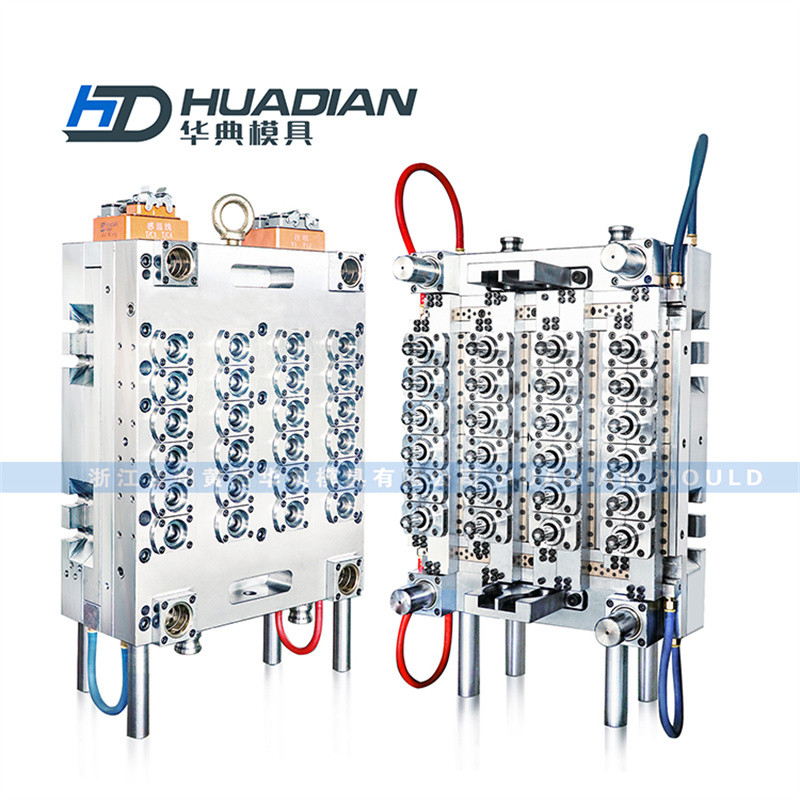

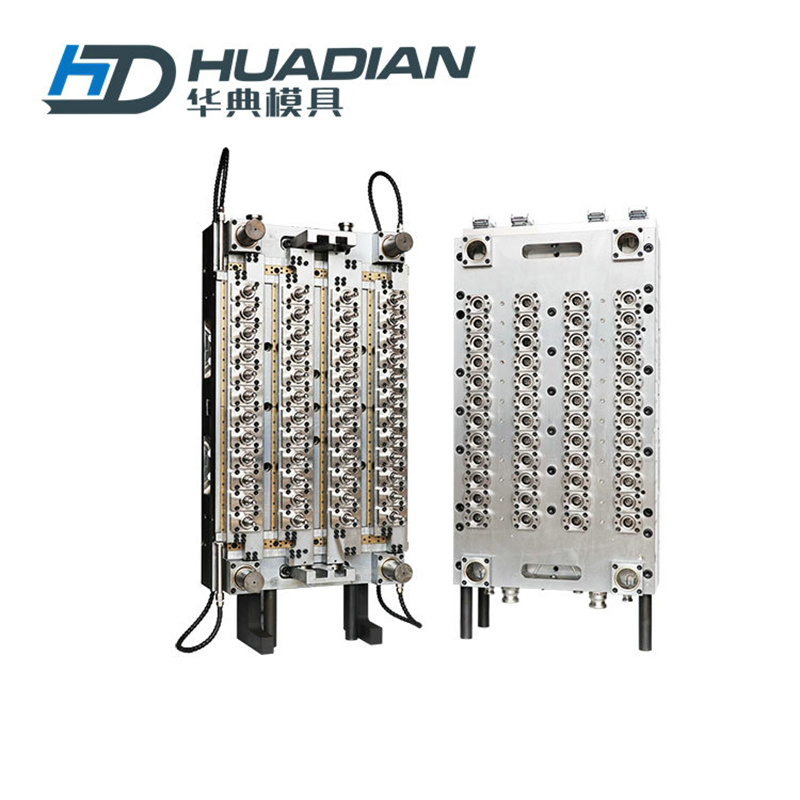

48 Cavities Perform Mold

Specifications

| Cavity | Perform | Mold Size | Mold Weight | Cycle Time | |||

| Weight(g) | Neck(mm) | Height(mm) | Width(mm)) | Thickness(mm) | (kg) | (sec) | |

| 2(1*2) | 720 | 55 | 470 | 300 | 608 | 330 | 125 |

| 4(2*2) | 720 | 55 | 490 | 480 | 730 | 440 | 130 |

| 8(2*4) | 16 | 28 | 450 | 350 | 410 | 475 | 18 |

| 12(2*6) | 16 | 28 | 600 | 350 | 415 | 625 | 18 |

| 16(2*8) | 21 | 28 | 730 | 380 | 445 | 690 | 22 |

| 24(3*8) | 28 | 28 | 770 | 460 | 457 | 1070 | 28 |

| 32(4*8) | 36 | 28 | 810 | 590 | 515 | 1590 | 28 |

| 48(4*12) | 36 | 28 | 1070 | 590 | 535 | 2286 | 30 |

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

HuaDian Mold - mold data

| NO. | Name | Desciption | Hardness | |

| 1 | Mold base material | P20 | 28-32 | |

| 2 | Core,cavity | S136 | 48-52 | |

| 3 | Screw neck | S136 | 48-52 | |

| 4 | Cooling mode | Mold core, neck cooling | ||

| 5 | Cooling mode for core plate and cavity plate | 1 in, 1 out | ||

| 6 | Out of center(MM) | "+/-0.08MM | ||

| 7 | Cycle injection time | 8-23 Seconds | ||

| 8 | Delivery time | 55 Days after desgins confirmed | ||

HUADIAN 48 Cavities Perform Mold is a mold specially designed for PET bottle production, which has the advantages of efficient production, high quality and low cost. It uses 48 cavities, each with a size of 4*12, using a hot runner system. Design and process through CAD, UG and other software to ensure accuracy and efficiency.

HUADIAN 48 Cavities Perform Mold is an efficient and high-quality PET bottle production mold. It adopts the design of 48 cavities, each cavity size is 4*12. Manufactured from high quality P20 material, cavity, core and screw openings are S136. The mold is designed and processed using CAD, PRO-E and UG software to ensure maximum accuracy and efficiency.

HUADIAN 48 Cavities Perform Mold adopts hot runner system, made of high-quality materials, with uniform heat flow, and the produced products have excellent quality and stability. The hot runner system can reduce material waste and reduce production costs. In addition, the hot runner system of this mold is designed to be very stable, which can prolong the life of the mold.

In addition, HUADIAN 48 Cavities Perform Mold also has a unique advantage, the attachment of the manipulator. It can automate production, reduce the risk of production operations, and improve production efficiency and quality. The automatic manipulator is easy to use and flexible, and is suitable for the needs of various manufacturers.

HUADIAN 48 Cavities Perform Mold is suitable for producing various PET bottles with simple operation and low cost. At the same time, it is suitable for various cosmetic manufacturers, has high mechanical stability, and can produce high-quality products in a short time. In addition, this mold has many other advantages, such as increasing production efficiency, producing high-quality bottles, reducing material waste, etc.

In conclusion, HUADIAN 48 Cavities Perform Mold is an efficient, high-quality and low-cost mold specially designed and produced for PET bottles. The design of 48 cavities can improve production efficiency, and the use of hot runner system and automatic manipulator can improve production quality and production speed. It is suitable for various cosmetic industries and PET product manufacturers, and can greatly improve production efficiency and quality.