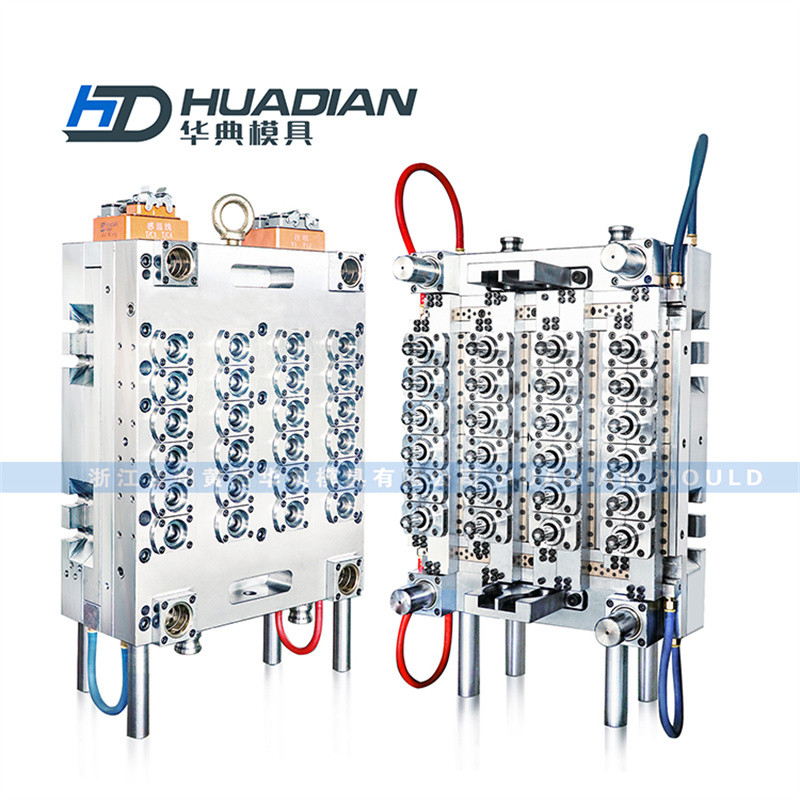

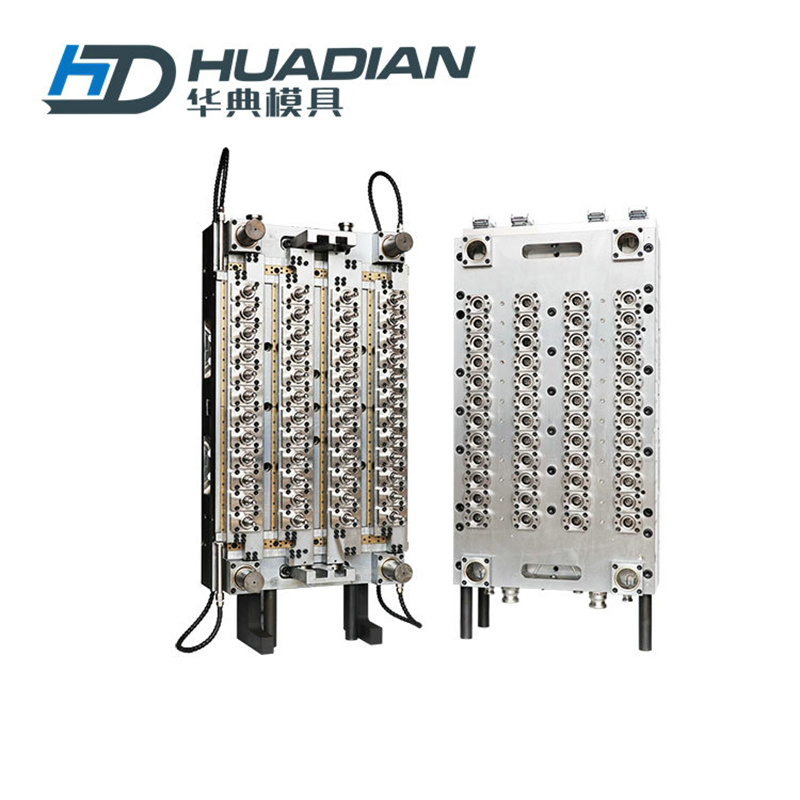

32 Cavities Perform Mold

Specifications

| Cavity | Perform | Mold Size | Mold Weight | Cycle Time | |||

| Weight(g) | Neck(mm) | Height(mm) | Width(mm)) | Thickness(mm) | (kg) | (sec) | |

| 2(1*2) | 720 | 55 | 470 | 300 | 608 | 330 | 125 |

| 4(2*2) | 720 | 55 | 490 | 480 | 730 | 440 | 130 |

| 8(2*4) | 16 | 28 | 450 | 350 | 410 | 475 | 18 |

| 12(2*6) | 16 | 28 | 600 | 350 | 415 | 625 | 18 |

| 16(2*8) | 21 | 28 | 730 | 380 | 445 | 690 | 22 |

| 24(3*8) | 28 | 28 | 770 | 460 | 457 | 1070 | 28 |

| 32(4*8) | 36 | 28 | 810 | 590 | 515 | 1590 | 28 |

| 48(4*12) | 36 | 28 | 1070 | 590 | 535 | 2286 | 30 |

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

HuaDian Mold - mold data

| NO. | Name | Desciption | Hardness | |

| 1 | Mold base material | P20 | 28-32 | |

| 2 | Core,cavity | S136 | 48-52 | |

| 3 | Screw neck | S136 | 48-52 | |

| 4 | Cooling mode | Mold core, neck cooling | ||

| 5 | Cooling mode for core plate and cavity plate | 1 in, 1 out | ||

| 6 | Out of center(MM) | "+/-0.08MM | ||

| 7 | Cycle injection time | 8-23 Seconds | ||

| 8 | Delivery time | 55 Days after desgins confirmed | ||

HUADIAN's 32-cavity hand-press bottle Perform Mold is a high-quality PET hand-press bottle mold, designed with hot runner system and CAD, UG and other software, each cavity size is 4*8, suitable for cosmetics and disinfection Liquid and other fields of production needs.

HUADIAN's 32-cavity hand-pressed bottle Perform Mold uses high-quality P20 mold material to ensure the strength and durability of the mold. Mold mandrel, cavity and screw opening are all made of S136 material to ensure product precision and life.

The mold is designed with hot runner system and CAD, UG and other software, which can maximize the filling and injection quality, improve production efficiency and product quality. The mold also uses high-quality materials from world-renowned brand manufacturers, such as the heat insulation cover of DOPONT in the United States, the band heater from HOSTET in Germany and the copper nozzle in Italy, etc., to ensure the quality of the mold.

In addition, the size of each cavity of HUADIAN's 32-cavity hand-pressed bottle Perform Mold has reached 4*8, and its 32 cavities can greatly improve production efficiency and produce more products faster. The mold also has an automated manipulator for ease of use to support efficient and accurate injection.

The mold is suitable for many fields, including cosmetics and disinfectants. By using HUADIAN's 32-cavity hand-pressed bottle Perform Mold, manufacturers can produce products more quickly and efficiently, and reduce production costs.

In conclusion, HUADIAN's 32-cavity Hand Press Bottle Perform Mold is a high-quality, high-efficiency, low-cost PET hand press bottle mold. Through state-of-the-art materials, technology and software, this tooling supports manufacturers in terms of product quality and productivity. If you are a manufacturer of cosmetics or disinfectants, or need to produce PET products, this mold is an indispensable choice for you.