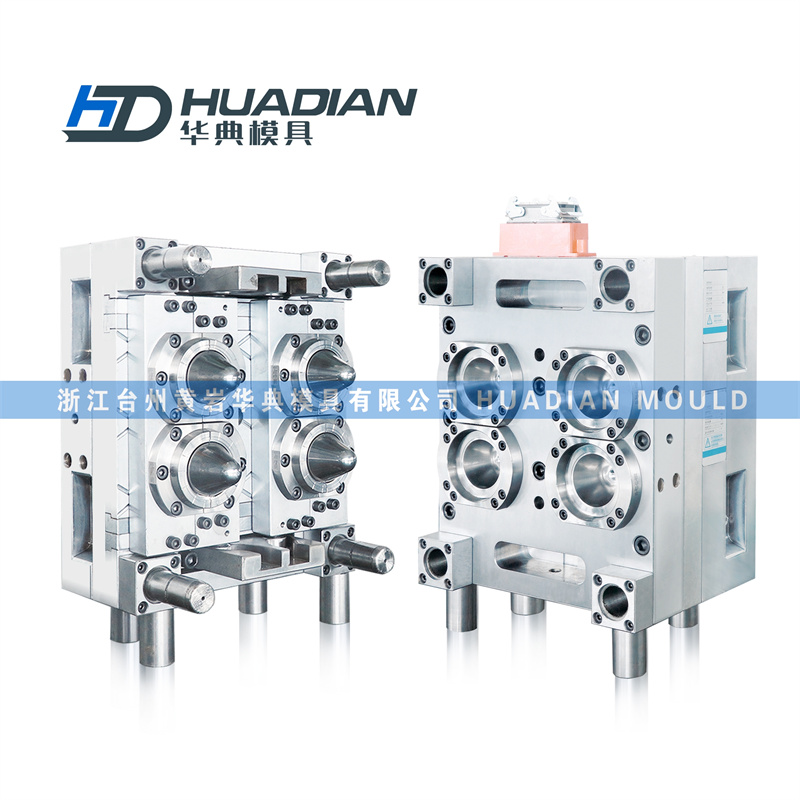

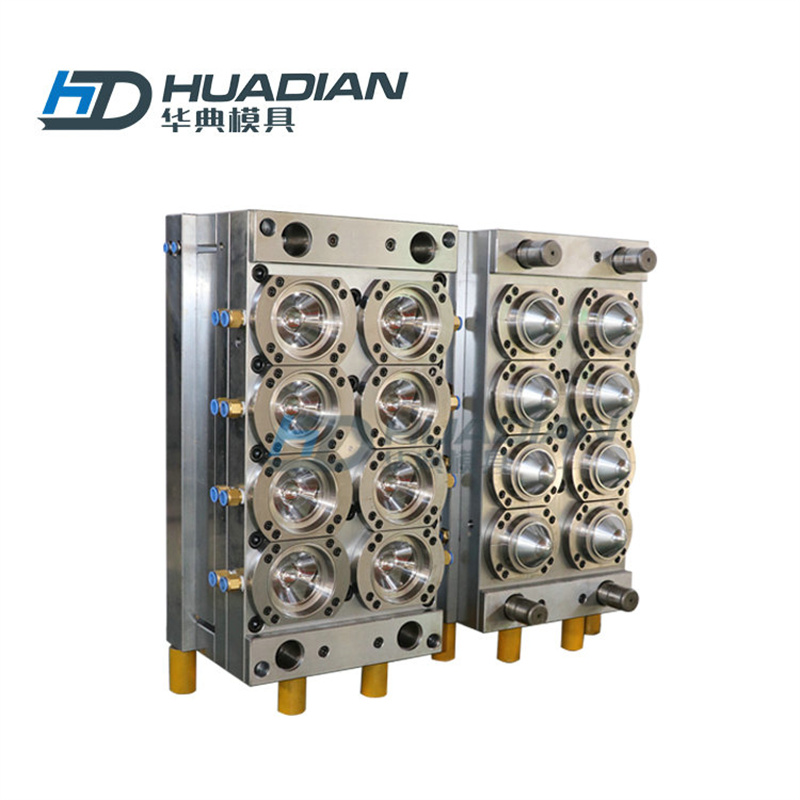

32 cavities hand sanitizer air-sealed preform mold

Product details

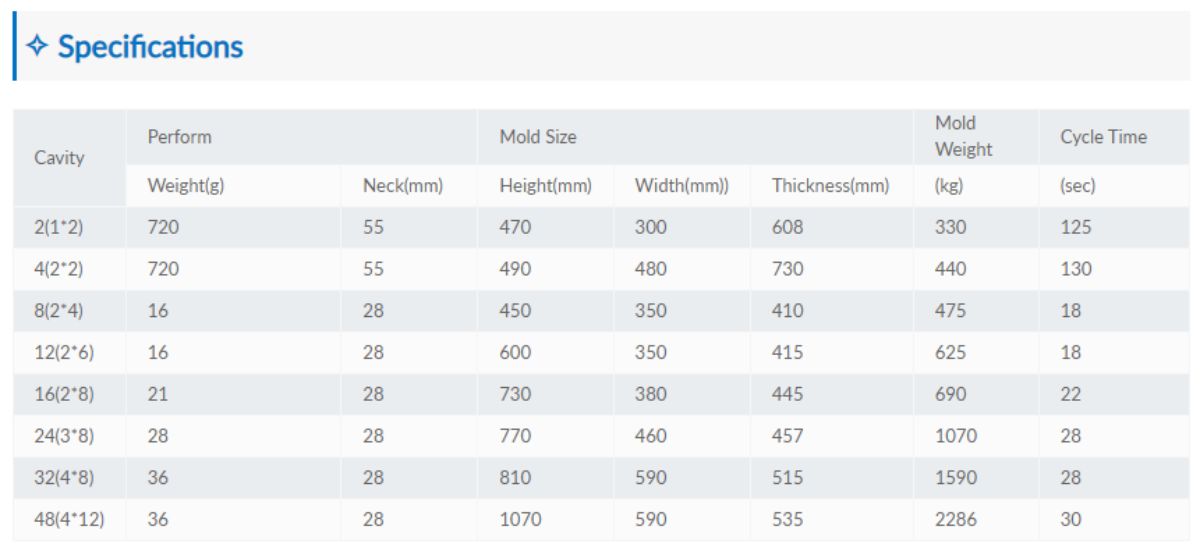

| Name | 32 Cavities Perform Mould |

| Country of Origin | Taizhou ,Zhejiang,China |

| Brand | HUADIAN |

| Cavity | 32(4*8) |

| Material of bottle | PET |

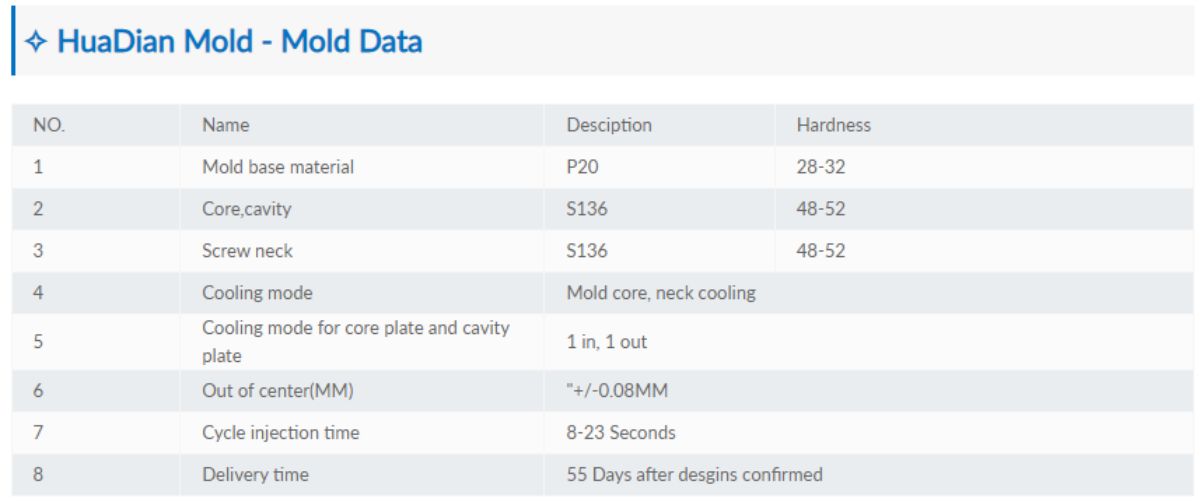

| Material of Mold | P20 |

| Material of Mold core, cavity,screw opening | S136 |

| Software | CAD, UG |

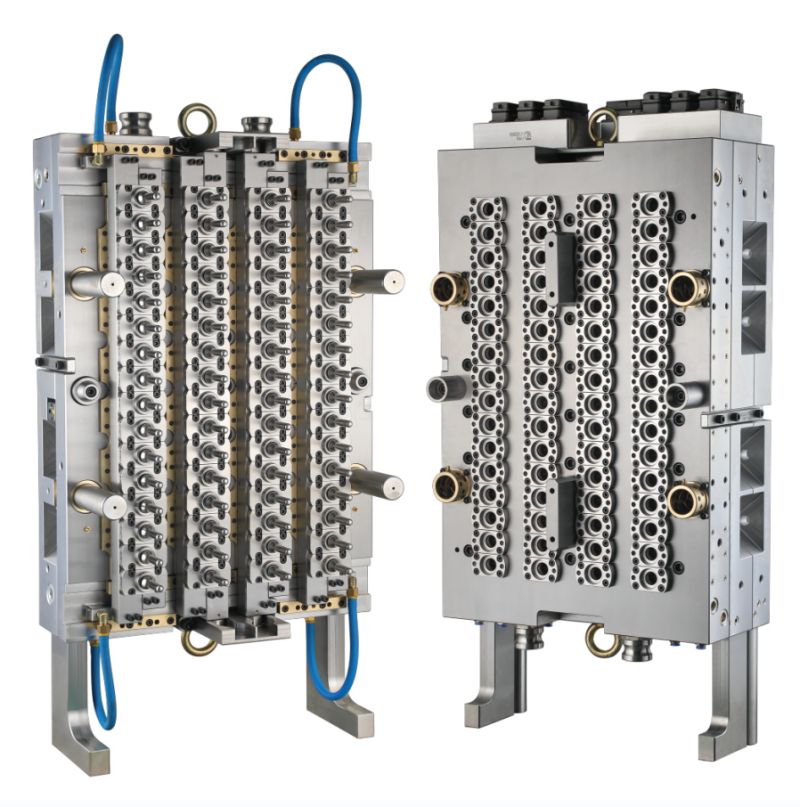

| Runner | Hot Runner |

Mold Components:all from World-famous manufactures, Insulation Caps from American DOPONT, Band Heater from Germany HOSTET, Copper Nozzl from Italy...

The Advantage On Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance Of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

The characteristics of PET raw materials in the bottle preform mold:

The raw material has the characteristics of low heavy metal content, low acetaldehyde content, good color value and stable viscosity. Due to the use of unique process formula and production technology, the product has excellent processing performance, low processing temperature, wide processing range, high product transparency, high yield, making the bottle process, high production efficiency, small degradation, low acetaldehyde content, while ensuring health and safety, effectively ensure the unique taste of pure water, mineral water, distilled water and so on.

(Good transparency gloss, colorless, odorless, non-toxic, chemical resistance, organic acid resistance, toughness, not easy to break. The mouth of the bottle has no rough edges, no burrs, clean and bright. The bottle is smooth without defects, no black spots without impurities, harmless to the human body and the environment, clean and healthy)