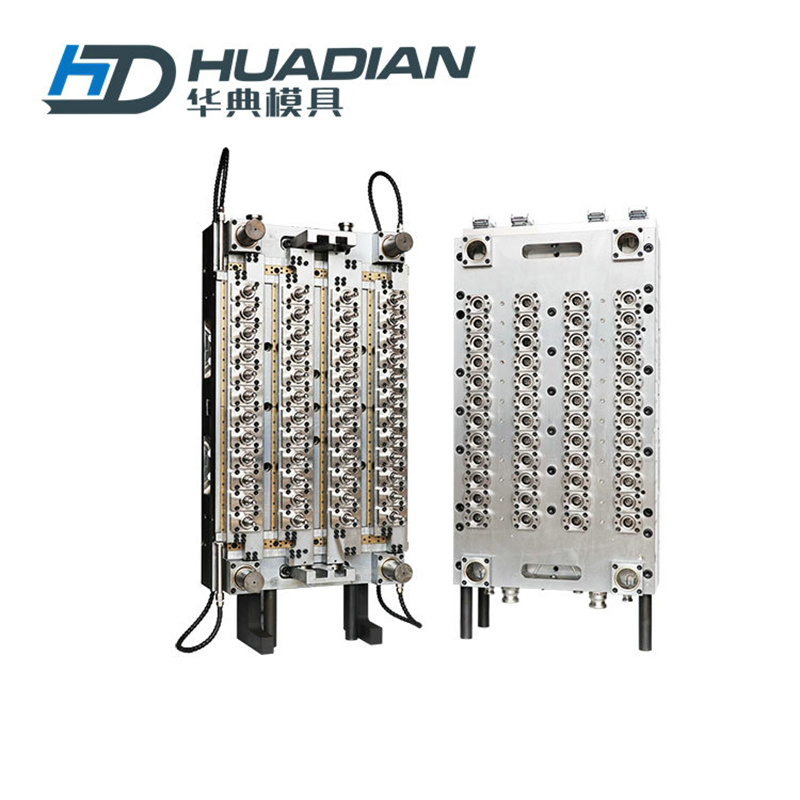

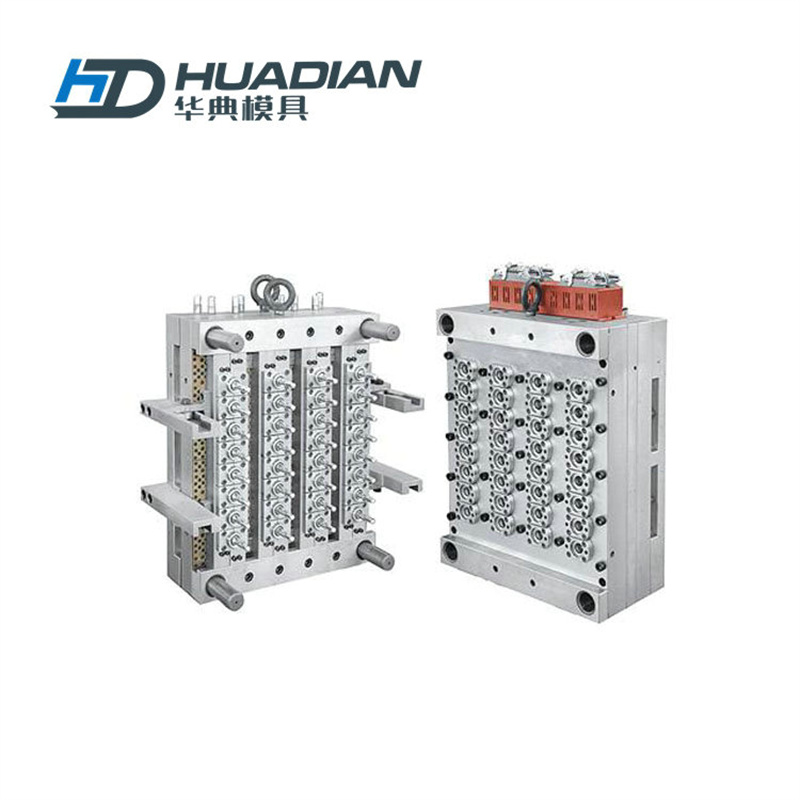

16 Cavities Oil Bottle Hot Runner Perform Mold

Specifications

| 0il Bottle Size | 1L-2.5L |

| 1.8L- 2.5L | |

| 10L | |

| 20L | |

| Neck | 32MM, 37MM, 46M, 46MM |

| 62MM, 72MK | |

| 0il Bottle Eight | 20G, 25G, 28G, 30G, 35G, 40G, 40G, 43G |

| 50G, 55C, 600, 63G, 65C. 680, 700, 756, 77G, 82G | |

| 85G, 90G, 93G, 95G, 100G, 120G, 140G, 145G, 150G | |

| 175C, 230C, 245G, 250G |

Product details

Taizhou Huangyan Huadian Mould Co., Ltd. is located in the famous mould town - Huangyan. More than 10 years of experience in preform mold, 1-96 cavity professional PET preform mold customization.

Main all kinds of water/beverage bottle preform mold, oil bottle preform mold, cosmetic bottle preform mold, all kinds of wide mouth bottle preform mold, as well as disinfection water, disinfectant, glass bottle preform, float bottle preform, etc., as well as a molding can product customization.

We have advanced mold processing equipment, cutting, grinding, drilling, boring, milling, turning, mold testing to measurement, independent processing, control all aspects of mold production, to ensure mold accuracy. In the design, we use CAD, UG, 2D&3D software for design, modeling and programming, and have the ability to manufacture high, fine and sharp molds. The mold material is carefully selected, and the spare parts are imported from foreign brands to ensure the quality of the mold. The mold production has the characteristics of fast mold production speed, high yield, transparent appearance, non-cutting gate, easy blow molding and so on.

At present, Huadian mold has been widely used in edible oil, beverage, candy, cosmetics, pesticides, medicine and many other packaging industries, with product quality, high efficiency, energy saving, long service life characteristics selling at home and abroad, the majority of users praise favor, exported to the United States, Europe, South America, the Middle East, Southeast Asia, Africa and other countries and regions, sales have risen steadily year by year.

Huadian mold, to promote the "Treat people with sincerity, based on the trust" entrepreneurial purpose, the pursuit of "quality zero failure, customer satisfaction" policy, to achieve stable quality, timely delivery, reasonable price, thoughtful service, customer satisfaction.

Warmly welcome new and old customers abroad to negotiate, come to visit!

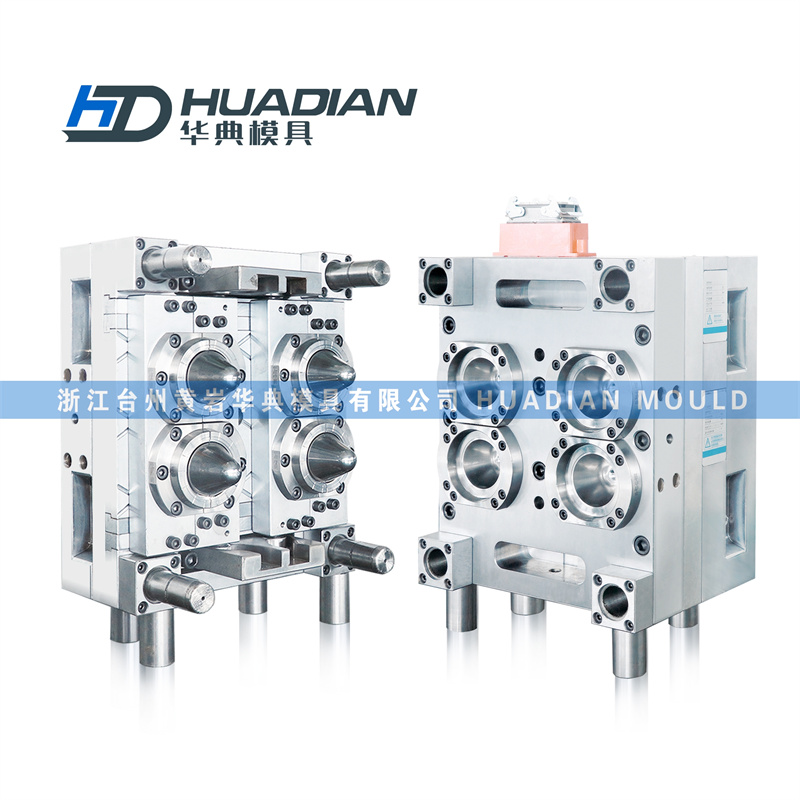

The Advantage On Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

HuaDian Mold - mold data

| Name | Pet Oil Bottl Perform Mold |

| Cavity And Core | S136(8, 12, 24, 48, 96HRC) |

| Mold Shelf | P20 |

| Cavity Qty | As Customi Zed |

| product Standard | Lkm, Dme, Hasco |

| Rotary Wheel Type | Hot Board |

| Cycle Time | Short |

| Software | UG, PROE, CAD |

| Perform Material | Pet |

| Perform SiZe | As Customi Zed |

| Working Life | 3-4Million |

| Delivery Time | 45-50DaysAYS |