12 Cavities Jar Customized Perform Mold

Product Video

Jar Size

- NECK: 60.5mm 70mm 70mm 86mm 86mm 110mm 70mm 86mm 63mm 120mm 97mm 86mm 120mm 120mm 120mm 122mm 120mm 148mm 62mm 71.5mm 71.5mm 71.5mm 71.5mm

- Weight: 30g 35g 43g 43g 52g 52g 53g 65g 65g 85g 88g 90g 95g 100g 120g 160g 170g 193g 150g 175g 250g 270g 290g

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

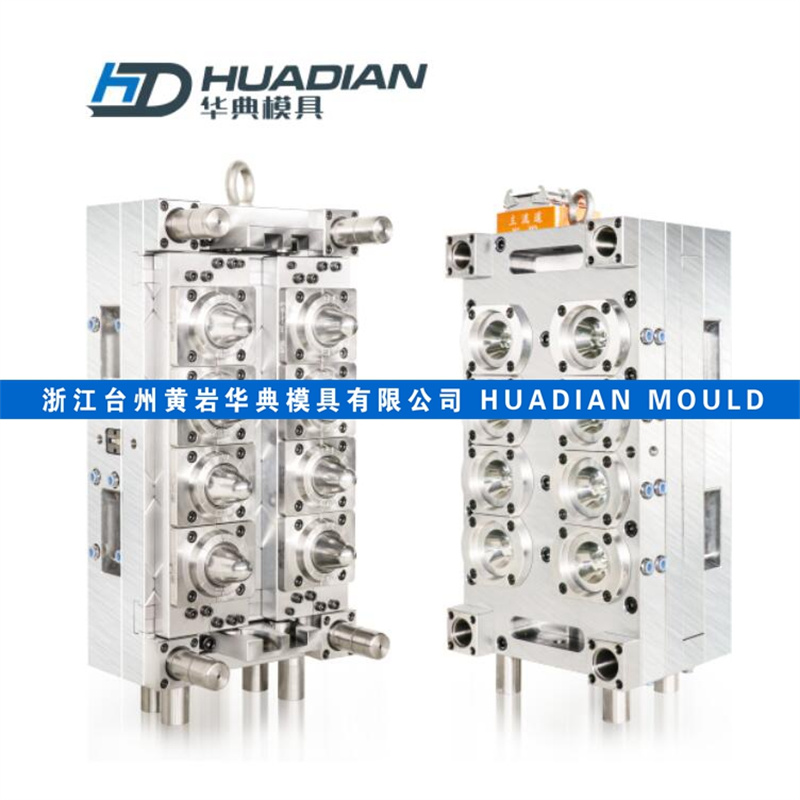

HUADIAN custom 12-cavity tank injection mold adopts high-quality PET material and hot runner design to ensure product accuracy and stability. Using high-quality P20 mould, S136 core, cavity and screw mouth, can produce high-quality PET jars. At the same time, the use of software CAD, PRO-E, UG optimizes the design, making it very easy to install and operate.

HUADIAN custom 12-cavity tank injection mold is produced with high-quality PET materials. The hot runner design reduces the material waste rate and ensures the high-quality production of PET tanks. The mold supports the output of 12 cavities, and the matrix layout of four rows and three columns is suitable for mass production. Made of high-quality P20 mold, the core, cavity and threaded mouth are made of S136 material to ensure the product accuracy and stability of PET jars.

The mold uses software such as CAD, PRO-E and UG for design optimization to ensure the accuracy and stability of PET cans. In addition, the mold is suitable for all kinds of PET cans, including food, cosmetics, household goods, etc., and can be customized according to customer needs.

The mold is easy to install and operate, and the installation and use manual describes each step in detail. In production, it is only necessary to keep each parameter within the specified range to ensure the high-quality production quality of PET cans and maintain stable production for a long time.

Summary: HUADIAN custom 12-cavity tank injection mold is a high-quality, easy-to-operate product that plays an important role in the production of PET jars. Made of PET material, the hot runner design reduces the material waste rate, and the combination of P20 mold and S136 core, cavity and threaded mouth ensures the product accuracy and stability of PET jars. It adopts design software such as CAD, PRO-E and UG to optimize, realize personalized production, and is easy to install and operate, which is very suitable for enterprises to carry out production and mass production.